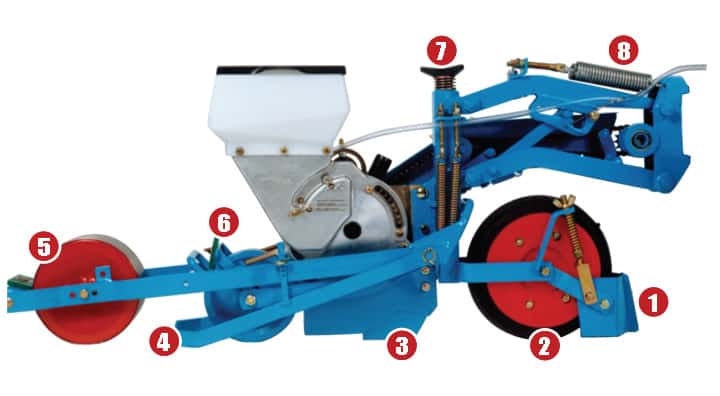

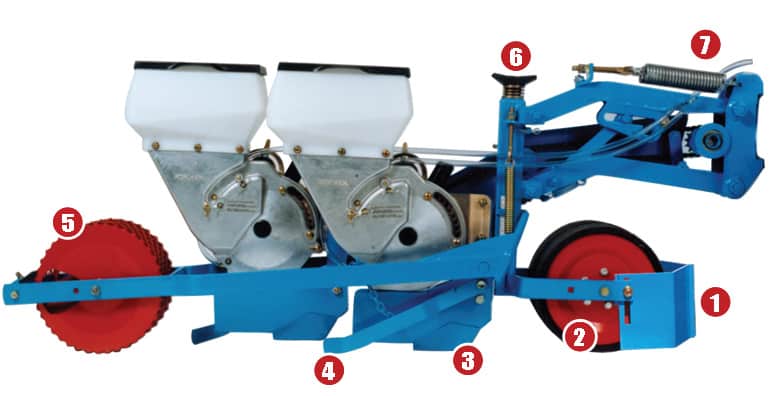

MS Mini-Seed Planters

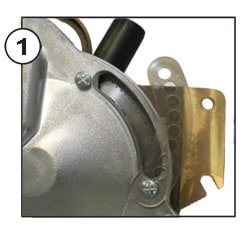

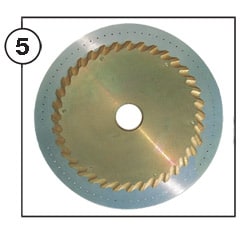

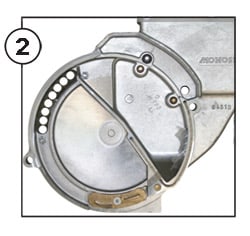

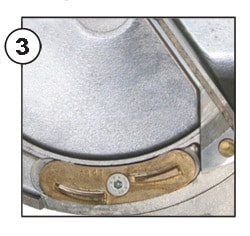

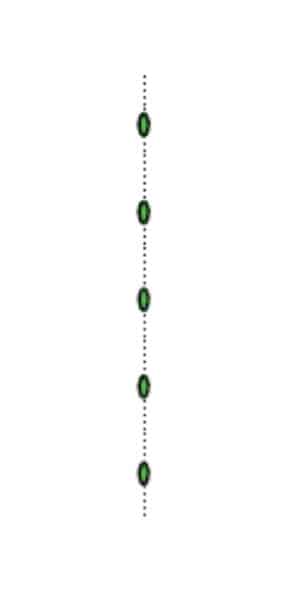

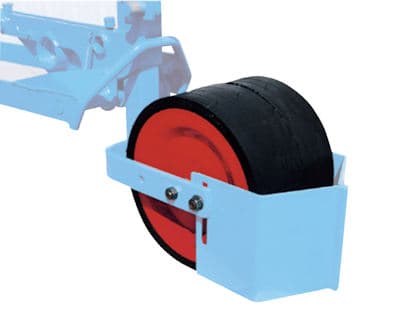

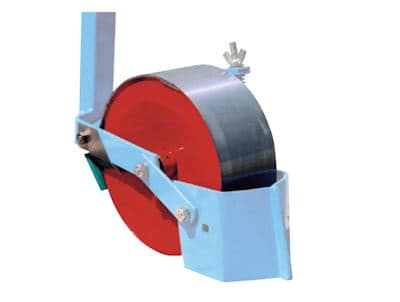

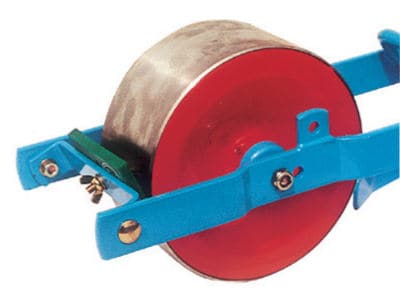

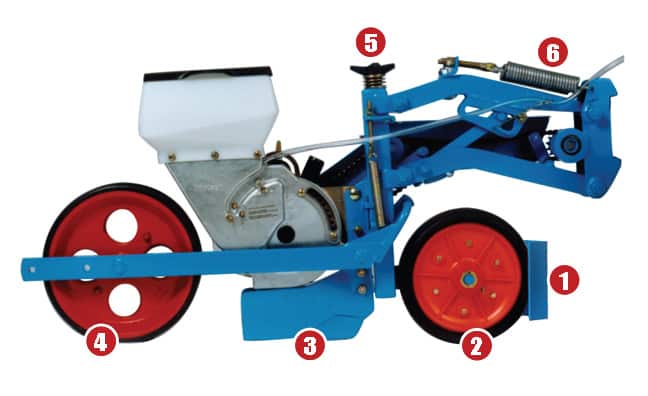

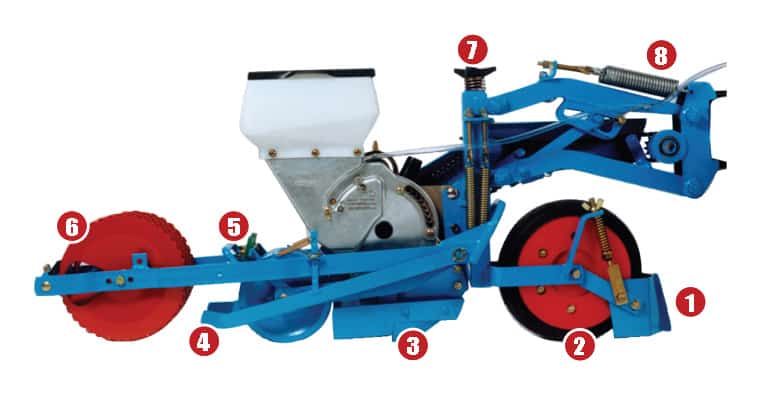

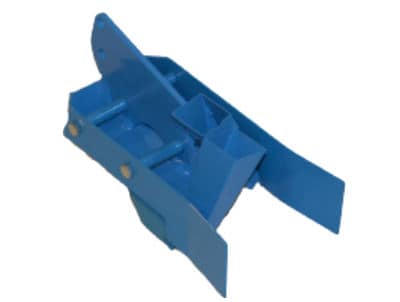

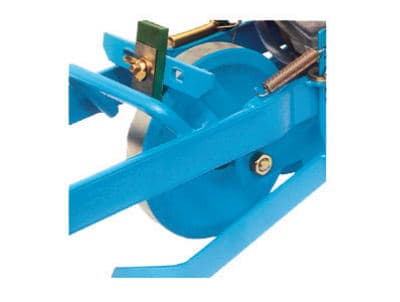

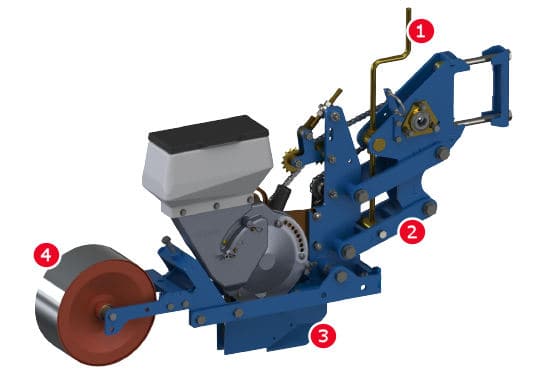

Monosem MS planters are designed to plant raw, encrusted, and pelleted seeds accurately thus reducing seed cost and thinning labor. The MS metering unit has been specially designed for small seed crops. The meter housing is made of brass and has a cast aluminum cover with an adjustable fiber seal to keep a tight fit. The seed is picked up by vacuum at a low point in the cover allowing the meter to plant even at a very low seed level. A shoe opener creates an extremely low seed drop to maintain proper seed spacing. The front gauge wheel provides consistent seed depth control while the intermediate press wheel and rear press wheel provide proper seed-to-soil contact for optimal emergence. The simplicity of adjustments make planting multiple vegetable crops quick and easy.

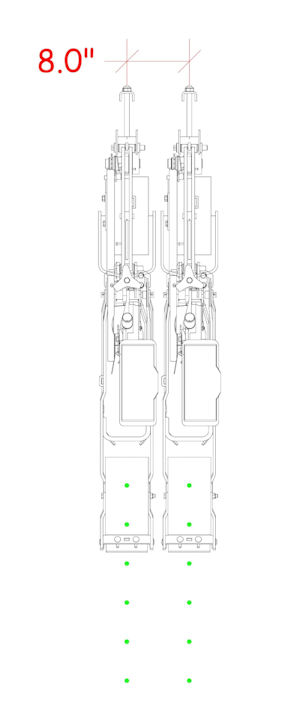

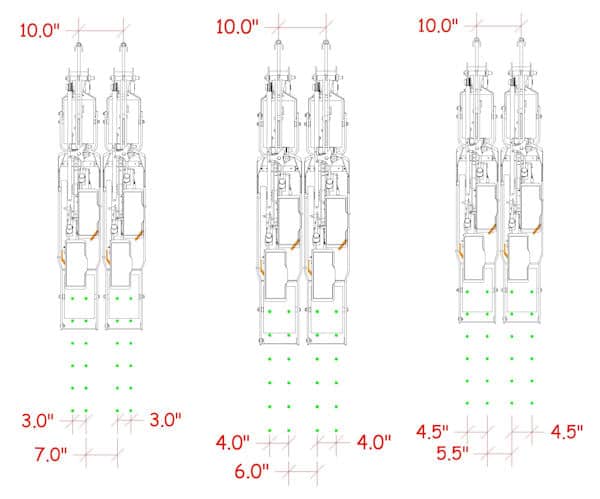

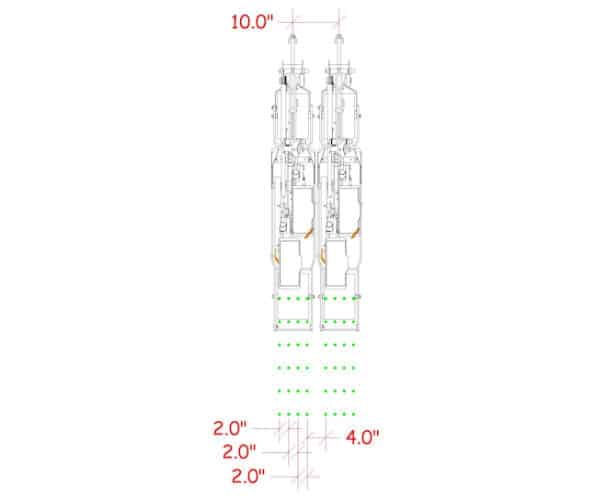

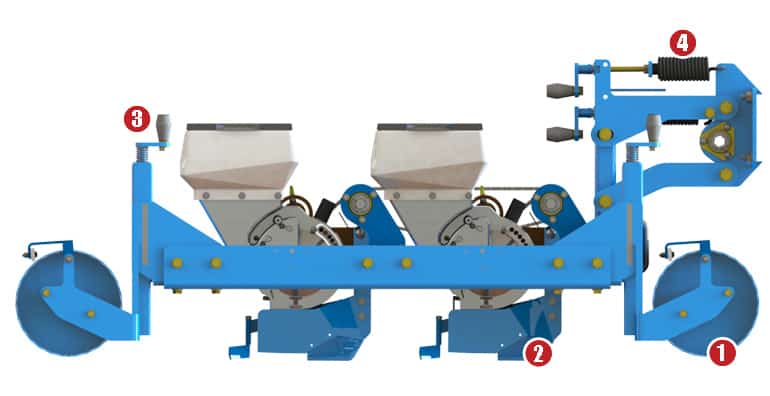

Monosem offers a wide range of row unit configurations to accommodate different line spacings and bed widths.

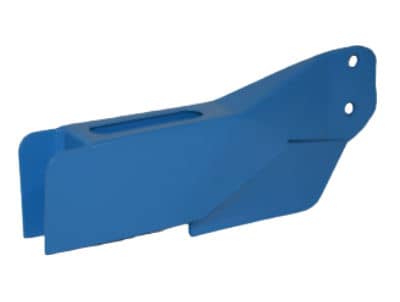

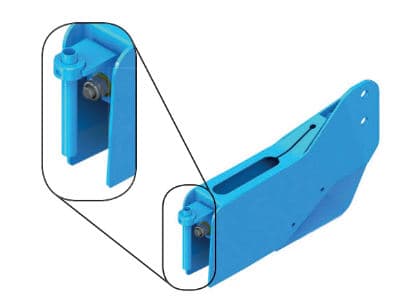

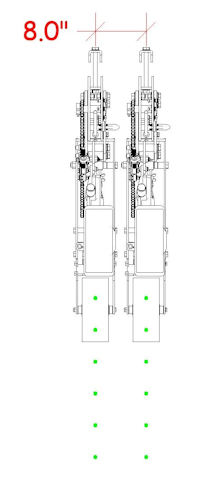

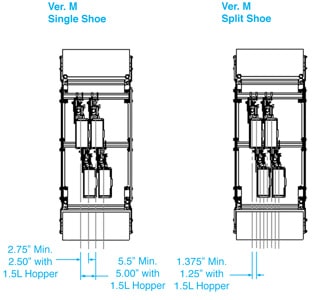

Single Seed line unit with a minimum row spacing of 8 inches, floating linkage with up pressure

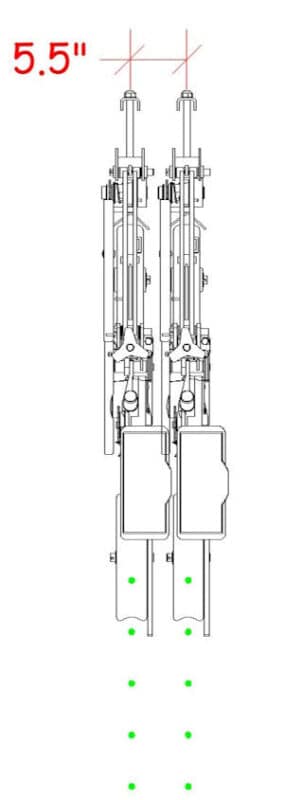

Single Seed line unit with a minimum row spacing of 5 ½ inches, floating linkage with up pressure

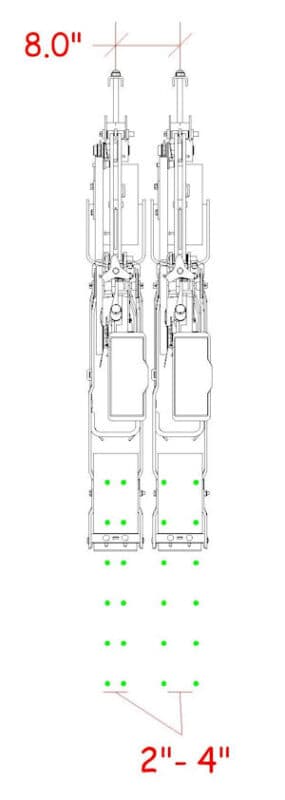

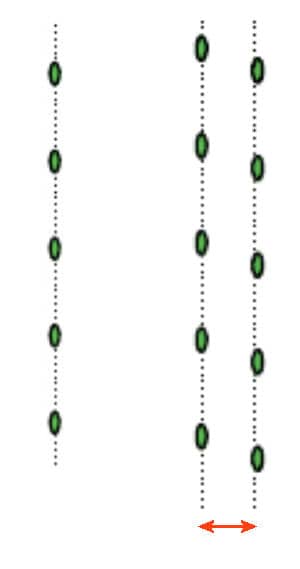

Twin Seed line unit with a minimum row spacing of 8 inches, uses a split shoe to achieve 2-4 inch spacing between lines, floating linkage with up pressure

Double row unit, with two metering boxes for single or twin Seed line, floating linkage with up pressure

Single Seed line unit Single Seed line unit with a minimum row spacing of 8 inches, non-floating linkage with screw adjust. Typically used in the light soils of the Yuma Arizona region